Metabolic & Bioprocess Engineering

2013

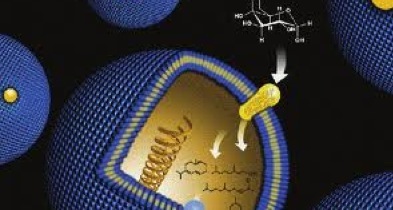

Industrial biotechnology – also known as white biotechnology – uses enzymes and micro-organisms to make bio-based products in sectors as diverse as chemicals, food and feed, healthcare, detergents, paper and pulp, textiles and bioenergy.

Industrial Biotechnology is a very promising field because of avoiding limited fossil resources as starting materials, but in some instances competing with edible feedstocks. This important issue, specially raised in the case of biofuels, can be solved by the introduction of 2nd generation biofuels using non-edible biomass as a sole feedstock. Besides biofuels, the wide variety of intermediate products that may enter at different stages in different value chains introduces complexity when analyzing biotechnological products. Because of its wide and diverse applications, industrial biotechnology is much more than a sole industrial or even economical sector. Companies manufacturing biotechnological products, such as bio-refineries, have a strong interdisciplinary approach in producing their bio-based products. In fact there is a claim for a bio-based economy.

Industrial or White Biotechnology that can be defined as follows: “Industrial biotech is the application of biotechnology for the industrial processing and production of chemicals, materials and fuels. It includes the practice of using microorganisms or components of micro-organisms like enzymes to generate industrially useful products, substances and chemical building blocks with specific capabilities that conventional petrochemical processes cannot provide.” Industrial biotechnology is mainly characterized by conversion of renewable biomass to products used in the consumer, chemical or energy industries. It could be distinguished from e.g., discovery research in pharma or agrochemicals, chemical transformation of renewable raw materials, biodiesel production from plant products, chemical degradation of organic waste materials.

Bio-based polymers are one of the important milestones on the white biotechnology's agenda. Over the past 20 years, these efforts have concentrated on polyesters of 3-hydroxyacids (PHAs), polylactic acid (PLA) and other polymeric building blocks such as 1,3-propandiol (1,3 PDO) or polyethylene from bioethanol which are mainly naturally synthesized by a wide range of microorganisms. These compounds could have properties similar to synthetic plastics and elastomers from propylene to rubber, but are completely and rapidly degraded by bacteria in soil or water. A major limitation of the commercialization of such bio-based plastics has always been their cost and performance in relation to petroleum-based polymers. Much effort has gone into reducing production costs through the development of better bacterial strains and/or the use of cheaper feedstocks, like food processing byproducts and waste, but recently alternatives emerged, e.g. the modification of plants to synthesize PHAs or the utilization of cellulosic feedstocks. Although bio-based polymers and plastics are still in their infancy, this industry has been characterised by an annual grow rate of almost 50% due to new synergies and collaborations. The global capacity of bio-based polymers was estimated to be 0.36 billion tones in 2007, with an annual growth rate of 48% in Europe and 38% globally, and its market share is expected to be 10-20% by 2020.

White Biotechnology

9/14/2556

Principle Investigator

Sunthorn Karnchanatawee, Ph.D.

Kaemwich Jantama, Ph.D.

Research Scientists